Why Corrugated Plastic?

Leading the Way in Sustainability

PP, together with PE, consumes the least amount of energy during production and produces the lowest carbon dioxide emissions when compared to other plastics.

Its lower density also means that switching to PP reduces the absolute amount of waste.

Parts made from PP can be recycled multiple times in a wide variety of applications before incineration is necessary.

When that time comes, it is possible to recover more energy from PP during incineration than from any other comparable plastic.

It also flows more easily as it degrades, without cross linking, gel forming or off-gassing.

Both Starbucks and McDonald's have switched to polypropylene cold cups rather than polyethylene terephthalate (PET), using less plastic and lowering their greenhouse gas emissions.

Quick Facts on the Sustainability of Polypropylene

Polypropylene produces less solid waste by weight than PET, PS or PVC

Polypropylene can be recycled into many applications, including battery cases, paint cans, home storage, flower pots, pallets, crates, composite lumber, and more.

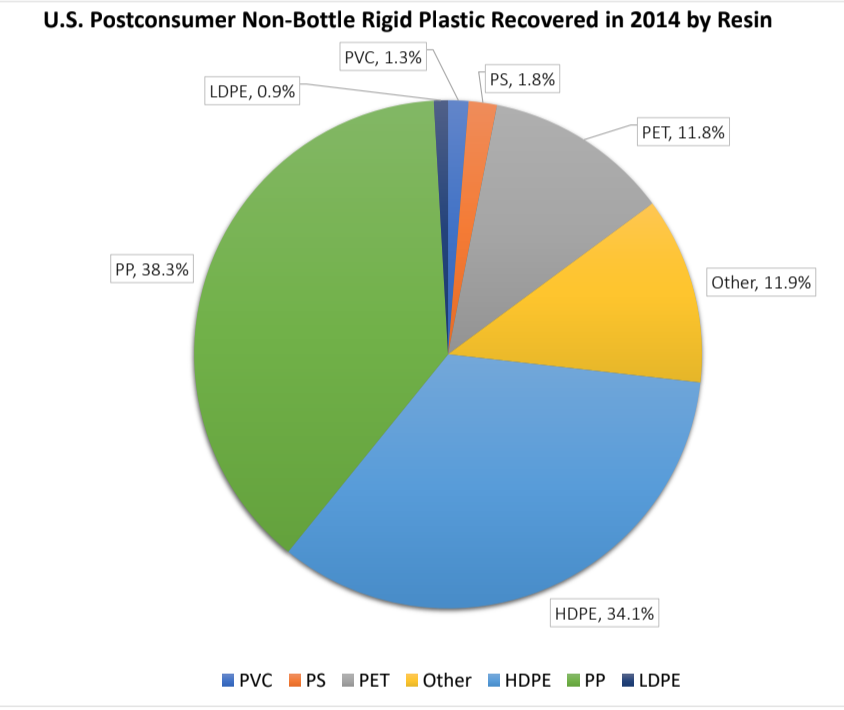

44 out of 51 the largest US municipalities by state collect polypropylene

Polypropylene and high-density polyethylene (HDPE) produce significantly less CO2 equivalents by weight than PET, PS, and PVC

Recyclable Polypropylene

Polypropylene parts can be 100% recycled into many applications.

There is an existing market for recycled PP (rPP) in a very wide range of products such as automotive applications, buckets, caps and closures, garden furniture, pallets, pipes, and more.

PLASTIC VS. CARDBOARD

Which is Greener?

When considered over the lifetime of the packaging, paper and cardboard embody far more greenhouse gases than their plastic equivalents.

This issue is an important one.

There is a heavy stigma viewing plastic as hazardous and paper-based goods as eco-friendly. But when considered over the entire life of the packaging, paper and cardboard embody far more greenhouse gases than their plastic equivalents. Paper products take substantial amounts of energy to make.

Crushing a tree down into small fibers, mixing the wood pulp into a slurry and then passing the wet mass through huge rollers cannot be done without use of enormous quantities of power. Making paper and cardboard is almost certainly the third largest industrial use of energy on the planet. By contrast, plastic is light, durable and its manufacture is generally not particularly energy intensive – at least by comparison to paper. A second concern is that many paper and cardboard products end up in local authority landfill, where they rot down anaerobically, creating the greenhouse gas methane in the process. Plastic, as is well known, doesn't rot and keeps its carbon forever.